The original hull and deck molds from the first generation builds were stored in a back yard. They had been subjected to heat and cold cycles and standing water. This had damaged the finish and caused some warping.

There were originally two molds. One for the hull and another for decks, gunwales, and seats. The generation 1 build process used lots of labor, filling and fairing to complete a skiff. We have eliminated the “parts and pieces” mold and will be molding in variable shaped core as part of our infusion build process. Separate table top molds, 3d printing and CNC machining will be used to build decks, seats, and other fittings.

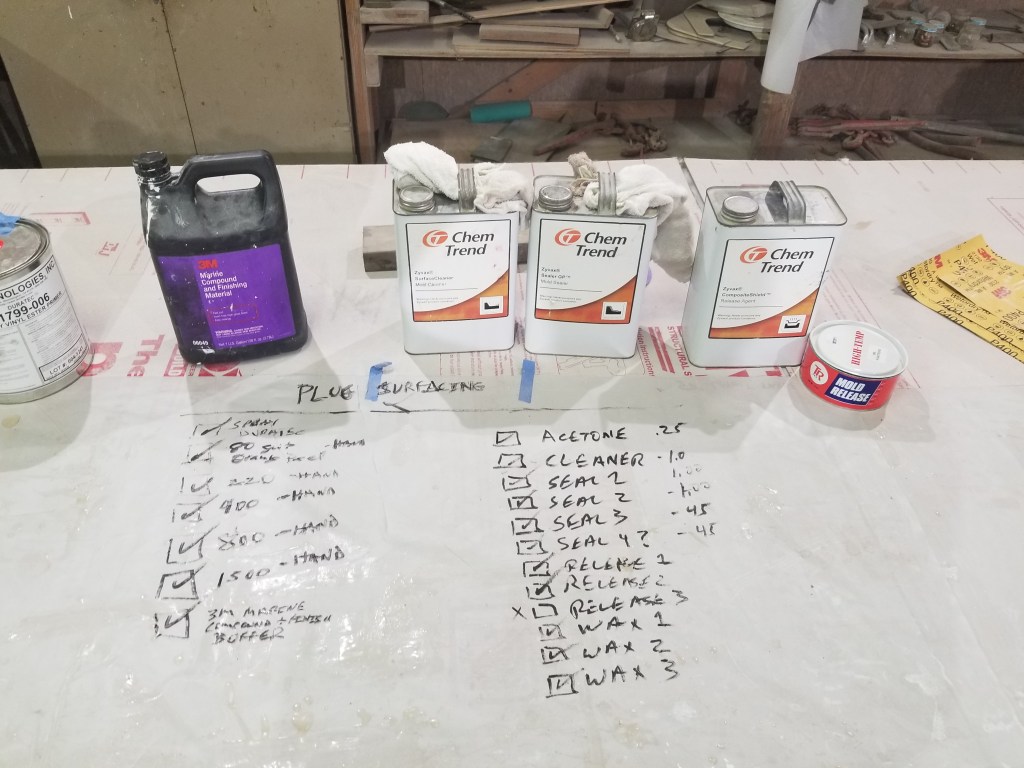

After building the prototype and working though what our future clean build process would require, we decided to build a new master “plug” using the old mold as the starting point. Below is the visual story (in reverse chronological order) of how this was accomplished: